AN INTRODUCTORY GUIDE TO

Black Soldier Fly Farming

Black Soldier Fly farming is shaking up the animal feed industry, offering an innovative approach to waste management and sustainable agriculture. These insects efficiently break down organic waste into nutrient-rich larvae used as livestock feed while minimizing methane emissions and waste sent to landfills, offering an appealing, green alternative to traditional methods.

This guide explores the process of Black Soldier Fly (BSF) farming, its agricultural applications, and the industry’s future, exploring the opportunities this transformative practice provides for a more sustainable feed industry system.

You will learn:

1. BSF Applications and Products

- Use of Black Soldier Fly Larvae as Feed

- The benefits of Frass

2. Breeding Black Soldier Flies

- Colony management

- Colony health and genetic diversity

- Environmental control

- Life Suspension technology (a reference to PauseM)

- Breeding models (sidebar)

3. Rearing Black Soldier Flies

- Types of facilities

- Common rearing methodologies

- Automation and Machinery

- Digital Monitoring and Data Analysis

- Processing and Harvesting

4. Environmental Impact and Sustainability

5. Future Prospects and Challenges

1. Black Soldier Fly Applications and Products

BSF farming offers a range of benefits for the agricultural industry, providing sustainable solutions to common challenges. From treating agricultural and food waste to providing an organic fertilizer of valuable proteins for feeding animals, the applications of Black Soldier Flies are diverse and far-reaching.

Use of Black Soldier Fly Larvae as Feed

The high protein content of Black Soldier Fly larvae makes them an ideal feed source for farm animals like poultry and piglets. As a sustainable alternative to traditional feed sources, Black Soldier Fly larvae offer a nutritious, healthy and sustainable option for farmers and animal feed producers looking for eco-friendly options to optimize their animal nutrition programs.

Aquaculture

One of the primary reasons for the increasing popularity of Black Soldier Fly larvae in aquaculture is their exceptional nutritional profile. These larvae are rich in protein, essential amino acids, and healthy fats, making them an ideal feed source for fish. Studies on Trout and shrimp have shown that diets supplemented with Black Soldier Fly larvae can enhance fish growth rates, improve feed conversion ratios, and boost overall fish health.

While Black Soldier Fly larvae offer numerous benefits, challenges such as scaling up production, ensuring consistent quality, and addressing regulatory considerations remain areas of focus for the industry. However, ongoing research and technological advancements are paving the way for overcoming these challenges and unlocking the full potential of Black Soldier Fly larvae in aquaculture.

Pet Food

BSF has gained traction as a sustainable and nutritious ingredient in pet food formulations. According to recent data, over 43 brands already include insect protein. This innovative approach to pet nutrition not only addresses environmental concerns but also offers significant health benefits for our beloved animal companions.

The nutritional composition of Black Soldier Fly larvae translates into tangible health benefits for pets. These benefits include improved digestion, enhanced immune function, healthier skin and coat, and overall vitality. Additionally, Black Soldier Fly-based pet foods are often free from common allergens and fillers, making them suitable for pets with sensitivities or dietary restrictions.

Poultry and Swine

BSF protein is gaining traction as a valuable source of poultry and piglet feed due to its impressive nutritional composition and sustainable production. Industry research on Poultry and also on Swine supports this trend, with studies showing that BSF larvae are rich in essential amino acids, protein, and healthy fats, making them an ideal dietary supplement for poultry and piglets. With the support of the European Union regulation, the use of BSF protein in feed formulations is increasing, reflecting the industry’s recognition of its nutritional benefits and environmental advantages.

The Benefits of Frass

Black Soldier Fly frass, the nutrient-rich excrement produced by BSF larvae, is emerging as a potent organic fertilizer with numerous benefits. Rich in nitrogen, phosphorus, potassium, and essential micronutrients, it enhances soil health and promotes robust plant growth and soil biodiversity while reducing the environmental impact associated with synthetic fertilizers. The EU Commission established a detailed definition of insect frass, categorizing it in the same group as processed animal manure and regulating its processing, introducing hygienic standards for insect frass.

2. BSF Farming: Breeding and Rearing

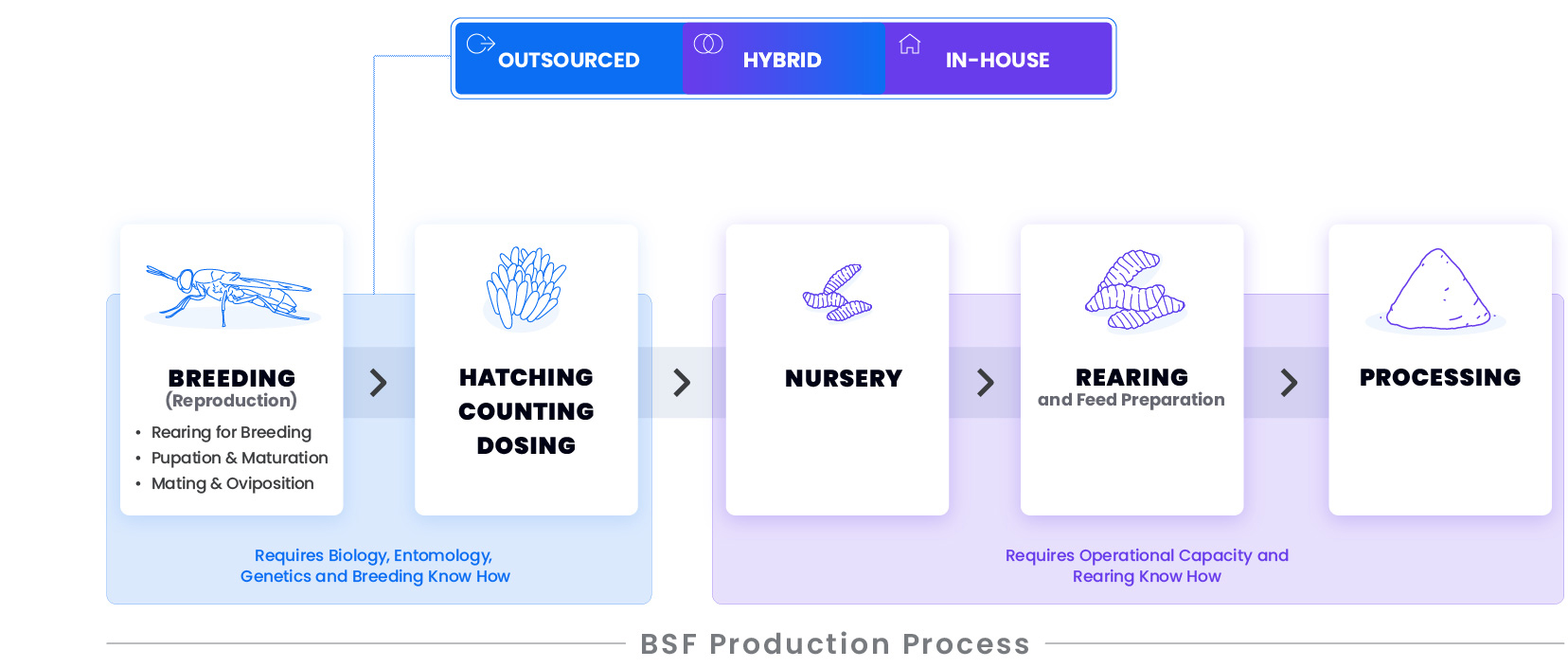

Black Soldier Fly farming involves two main distinctive parts: breeding (reproduction) and rearing/processing. Whist breeding focuses on producing a steady supply of healthy larvae using specialized knowledge, and the rearing and processing aims to convert the larvae into valuable products efficiently.

The insect breeding or reproduction phase requires a deep understanding of biology to optimize the conditions for mating and egg production. Breeders set up a lab, maintain colonies, and adjust environmental factors to encourage the production of healthy larvae. Incubated eggs then hatch into larvae, which are fed food waste “formulas” to stimulate growth.

The next phase involves rearing and processing. In this stage, similar to a traditional food chain, mature larvae are harvested and processed into products such as protein, fertilizer, and oil. Rearing focuses on managing the larvae’s environment and feed, ensuring constant growth. Processing involves converting the larvae into a saleable form, mirroring traditional food production principles.

Breeding Black Soldier Flies

Effective insect farming relies on techniques and best practices to increase breeding productivity. The correct methods can help improve insect production, keep insect colonies healthy, and produce top-quality insect-based products. Here are key points to remember:

Colony Management

Colony management: Proper management ensures healthy and productive insect colonies. This includes mimicking the insects’ natural habitat through ideal housing conditions like suitable temperature, humidity, and ventilation. Regularly monitoring colonies to detect signs of stress, diseases, or overcrowding safeguards the insects’ well-being.

Managing a Black Soldier Fly colony entails several challenges, particularly ensuring a stable egg output for consistent production. Fluctuations in environmental factors can disrupt egg-laying cycles, leading to irregular egg production. Additionally, managing colony hygiene and preventing the buildup of pathogens or pests is essential to sustain a healthy and productive BSF population.

Environmental Control

Farming facilities need the right systems to regulate environmental factors like temperature, humidity, and lighting, all of which significantly affect insect growth and productivity. Monitoring and adjusting these parameters creates optimal conditions for insects. The regulation considers BSF to be livestock. It’s crucial to maintain BSF’s good hygiene in farming facilities to prevent diseases and ensure the quality of insect-based products. Regular cleaning and disinfecting of equipment, housing units, and feeding areas help minimize contamination risks.

Colony Health

Maintaining the health and genetic diversity of a BSF colony is paramount for sustainable insect production. Best practices for colony health include regular monitoring of population dynamics, disease prevention through biosecurity measures, and maintaining optimal environmental conditions. Introducing genetic diversity through periodic introductions of new genetic material or strains helps prevent inbreeding depression and promotes robustness within the colony. Additionally, implementing strict hygiene protocols, providing balanced nutrition, and minimizing stressors such as overcrowding contribute to overall colony health and longevity.

Life Suspension Technology

Preservation techniques like FreezeM’s proprietary live suspension technology, called PauseM®, temporarily stop the BSF life cycle at various stages, marking the advent of controlled insect farming for the first time.

The capability to pause the BSF neonate life cycle for 21 days facilitates the establishment of breeding hubs designed to streamline outsourced breeding in a Breeding-as-a-Service model, catering to diverse rearing and processing needs across various facilities globally.

Three Flexible Breeding Models

While the in-house model was the preferred breeding choice for insect farming companies in the early days of the industry, it is now clear that this approach involves many risks that are unfavorable to investors and companies seeking rapid growth.

Outsourced Breeding

Establishing a breeding unit requires approximately 20% of the overall factory cost and area. In addition, it requires specialized personnel with expertise in biology, entomology, and genetics. Leaving the breeding hassle with FreezeM eliminates the need to develop a reproduction line, hatching, and dosing technologies.

Hybrid Breeding Model

When taking a hybrid in-house and outsourced reproduction approach, farmers can choose to replace a significant part of their breeding with outsourced supply to make their in-house breeding processes more efficient and more standardized, ensuring production contingency.

In-House Breeding Model

Vertically integrated farms include breeding processes in-house. These require strict control over colony management, environmental control, and colony health, as seen above. It’s good practice to supply these BSF colonies with periodic genetic boosts from different BSF lines. Such genetic enrichment results in a healthier colony, with improved neonates’ robustness, growth, and stability.

3. Rearing in Black Soldier Fly Farming

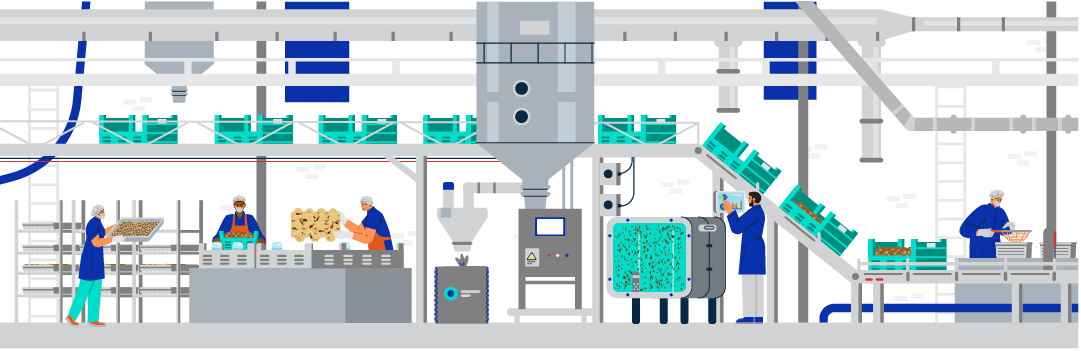

In recent years, technological advancements have transformed how Black Soldier Fly farms operate, paving the way for improved efficiency, productivity, and scalability. From automation and machinery to digital monitoring and data analysis, these innovations have revolutionized how Black Soldier Fly larvae are produced and harvested.

In this section, we will explore the cutting-edge technologies reshaping the Black Soldier Fly farming industry and driving its growth.

Types of Facilities

BSF rearing can be approached at different scales, ranging from container modules suitable for small-scale farms to large-scale factories. Each approach to BSF rearing scale has its advantages and considerations, depending on factors such as available space, production volume, investment capacity, and market demand.

An important concept in BSF rearing is bringing the larvae to the waste rather than transporting the waste to the larvae.

This approach minimizes logistical complexities and ensures efficient utilization of organic waste streams. Therefore, these facilities are ideally implemented near waste sources such as food processing plants, agricultural operations, or urban centers to facilitate easy and cost-effective transportation of waste materials to the BSF rearing facilities. This proximity not only lowers transportation costs but also reduces the carbon footprint associated with waste disposal and insect production.

Container Modules

Container modules are compact systems that can be set up in limited spaces, making them ideal for urban or backyard farming setups. These modules typically consist of trays or containers for rearing BSF larvae, allowing for controlled conditions and efficient management of small batches.

Small Farms

Small farms may employ slightly larger setups, utilizing multiple container modules or dedicated rearing areas to produce BSF larvae in moderate quantities.

Large Facilities

On the other end of the scale, large-scale factories employ sophisticated rearing facilities with automated systems, climate control, and optimized processes to produce BSF larvae on a commercial scale.

Common rearing methodologies

BSFrearing methodologies encompass distinct stages, including nursery and rearing phases, often utilizing tray-to-tray or batch nursery systems. In the nursery stage, BSF eggs are incubated and hatch into larvae, which are then transferred to rearing trays or containers.

-Tray-to-tray nursery systems involve a continuous transfer of larvae from smaller to larger trays as they grow, allowing for efficient space utilization and management of larval densities.

-Batch nursery systems, on the other hand, involve rearing larvae in larger containers or tanks without transferring between trays, simplifying the rearing process but requiring careful monitoring of larval development and overcrowding.

Each methodology offers unique advantages and challenges, requiring farmers to consider factors such as space availability, labor efficiency, and optimal larval growth conditions when choosing a suitable BSF-rearing approach.

Automation and Machinery

Automation has revolutionized BSF farming, streamlining production processes and reducing labor costs. Modern farms are equipped with automated feeding systems, temperature control mechanisms, and larvae harvesting technology, enabling farmers to maintain optimal growth conditions and maximize yields.

Digital Monitoring and Data Analysis

Digital monitoring and data analysis have become essential tools for optimizing Black Soldier Fly farming operations. Through the use of sensors, cameras, and software systems, farmers can monitor critical parameters such as temperature, humidity, and larvae growth rates in real-time. This data is then analyzed to identify trends, optimize feeding schedules, and make informed decisions to improve farm productivity.

Innovation in Processing and Harvesting

State-of-the-art equipment, such as automated larvae separators, drying machines, and packaging systems, has streamlined the post-harvest process, guaranteeing product quality and consistency. Innovations in BSF processing and harvesting techniques have become a key focus in the insect farming industry, especially regarding the comparison between wet processing and dry processing methods.

–Wet processing involves using water or steam to separate larvae from their substrate, followed by methods such as boiling, drying, and milling to produce insect meal or oil. This method is efficient in extracting high-quality protein and nutrients but requires significant water usage and energy input.

–Dry processing utilizes mechanical separation techniques such as sieving and air-drying to extract larvae and produce insect-based products. While dry processing reduces water consumption and energy costs, it may result in lower nutrient retention and product quality compared to wet processing. Ongoing research and technological advancements aim to optimize both wet and dry processing methods, balancing efficiency, sustainability, and product quality in BSF processing and harvesting for diverse applications in agriculture, aquaculture, and animal nutrition.

4. Environmental Impact and Sustainability

Black Soldier Fly farming has gained recognition for its positive environmental impact and contribution to sustainability. By leveraging the natural capabilities of these insects, farmers are able to address key environmental challenges such as waste management, resource efficiency, and the promotion of circular economy principles.

Black Soldier Fly Farming and Reduced Waste

One of the most significant benefits of Black Soldier Fly farming is its ability to reduce organic waste. These voracious larvae are highly efficient at converting organic matter into nutrient-rich biomass, making them ideal candidates for waste management solutions. By feeding on organic waste streams such as industrial food waste, and agricultural by-products, Black Soldier Fly larvae not only divert waste from landfills but also generate valuable resources that can be used as animal feed, fertilizer, or renewable energy sources. This closed-loop system helps to minimize waste generation and promotes a more circular approach to waste management.

Carbon Footprint and Resource Efficiency

Black Soldier Fly farming offers a sustainable alternative to traditional livestock farming practices, known for their high carbon footprint and resource-intensive nature. By requiring fewer inputs such as water, land, and feed than conventional livestock production, Black Soldier Fly farming is inherently more resource-efficient and environmentally friendly.

Contribution to Circular Economy

Black Soldier Fly farming is at the forefront of the circular economy movement, where resources are utilized in a closed-loop system to minimize waste and maximize efficiency. By converting organic waste into animal feed and fertilizer for agriculture, which will eventually return to be organic waste, Black Soldier Fly farms contribute to the circularity of resources, creating a more sustainable and resilient agricultural system.

5. Future Prospects and Challenges of BSF Farming

As Black Soldier Fly farming continues to gain momentum as a sustainable solution for waste management and protein production, the industry faces both opportunities and challenges. In this section, we will explore the future prospects and potential obstacles facing Black Soldier Fly farming as it strives to establish itself as a mainstream agricultural practice.

Opportunities for Growth in Black Soldier Fly Farming

The growing demand for sustainable protein sources, coupled with increasing awareness of the environmental benefits of Black Soldier Fly farming, presents significant opportunities for growth in the industry. With a market potential in animal feed, aquafeed, and bioenergy sectors,

Black Soldier Fly farming is poised to expand and become a key player in the sustainable protein market. As more farmers and investors recognize the value of Black Soldier Fly larvae as a resource-efficient and environmentally friendly alternative to traditional livestock feed, the industry is expected to experience rapid growth in the coming years.

Regulatory and Legal Considerations

Despite its promising potential, Black Soldier Fly farming faces regulatory and legal challenges that may impact its scalability and commercialization. As a novel agricultural practice, Black Soldier Fly farming is subject to varying regulations and guidelines in different regions, which can create barriers to market entry and hinder industry growth. Clear and consistent regulatory frameworks, as well as collaboration between stakeholders and policymakers, are essential to facilitate the development of a supportive environment for Black Soldier Fly farming and ensure its compliance with industry standards.

Research and Development in the Field

Research and development play a crucial role in driving innovation and advancing the capabilities of Black Soldier Fly farming. Continued research efforts in insect nutrition, breeding, larvae processing, and product development are essential to optimizing production processes, enhancing product quality, and unlocking new market opportunities for Black Soldier Fly larvae. Collaboration between academia, industry, and government institutions is key to fostering a culture of innovation and knowledge exchange in Black Soldier Fly farming, paving the way for future advancements and breakthroughs in the industry.

6. Conclusion

Black Soldier Fly farming has the potential to revolutionize the agriculture industry by providing a sustainable solution for protein production and waste treatment. Its resource-efficient and eco-friendly practices address critical challenges in food production and waste management, contributing significantly to a more sustainable and circular economy.

As we look ahead, the industry is at a pivotal moment of growth and innovation, with opportunities for expansion and market adoption, such as the recent EU approval of BSF larvae as livestock feed. Overcoming regulatory challenges, supporting research and development, and collaborating with stakeholders can establish Black Soldier Fly farming as a mainstream agricultural practice, leading to a more sustainable food system.

The transformative impact of Black Soldier Fly farming on agriculture is undeniable, promising a more sustainable and prosperous future for the industry and beyond.

FreezeM

FreezeM stands at the forefront of advancing Black Soldier Fly (BSF) reproduction, offering a unique blend of cutting-edge technology and strategic assistance to businesses navigating the dynamic insect-based protein industry. One of FreezeM’s pioneering solutions is the introduction of PauseM® patented suspended BSF neonates, a breakthrough that reshapes farming and waste management processes. This technology not only optimizes control and efficiency in BSF reproduction but also streamlines the overall approach. FreezeM is actively contributing to the evolution of insect-based protein production by incorporating state-of-the-art techniques to address the increasing demand for sustainable protein sources while overcoming challenges in traditional farming methods.

In alignment with Environmental, Social, and Governance (ESG) initiatives, FreezeM places a strong emphasis on sustainability. The company actively participates in waste reduction and sustainable agriculture through its BSF reproduction solutions, supporting customers in their commitment to ecofriendly practices. FreezeM’s dedicated team plays a pivotal role in easing the onboarding process for new market entrants, facilitating a smooth entry into the insect-based protein sector. For large enterprises, FreezeM provides valuable support in efficiently expanding BSF operations, and navigating potential challenges associated with cost and time constraints. Recognizing the diverse objectives of businesses, FreezeM offers tailor-made, ready-to-use solutions, ensuring that the implementation of BSF reproduction aligns seamlessly with the specific goals and requirements of each customer.